Developed by Tosilon Tech-Flow Division, BCS (Batch Control System) is customer oriented focusing on precision metering control system. Combined with experiences engaging in metering filed covering Petrochemical, Fine Chemical Industry, Pharmaceutical Industry, etc., Tosilon's BCS system is becoming one of the important part among production scheduling, logistics arrangement and safety protection.

The "Modularization" and "Standardization" of the BCS makes it possible for the system to meet various demands. The "Standardization" makes it easier to have the system upgraded, Extended and Maintained, which help to improve the quality control for the production process. This design helps reducing the deliver cycle and offering wide options for metering application.

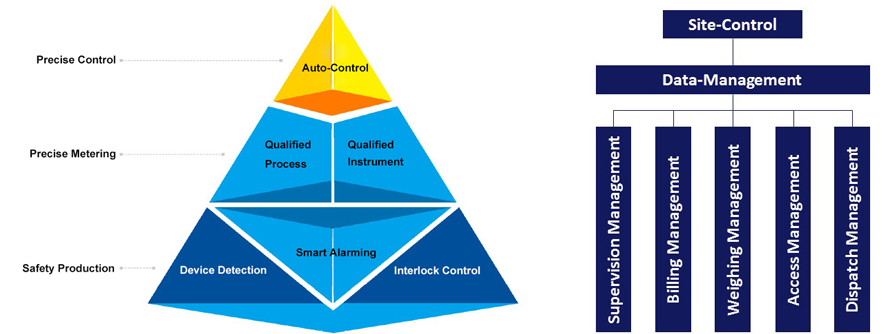

BCS Concept

| Safety Production | Equipped with Safety Detection Device, collecting alarming information, the "Smart Alarming" and the "Interlock Control" guarantee the safety production |

| Precision Metering | The systems satisfy the flow meter working condition, having the flow meter keep stable performance. |

| Precision Control | Based on process requests, system is able to be equipped with appropriate device. |

BCS-100 System

| Typical Application | Batch Filling Control of the Liquids |

| Quantitative Filling Control of the Liquids |

| Site Control |

Signal-Collection of the Site-Device; Display Alarming Information |

| Data-Management | Processed by OPC Data Server |

| Supervision Management |

Site Centralized Monitoring; Historical Data Query; Historical Data Curves |

| Billing Management |

Billing for Delivery of Cargo from Storage; Account Data Statistics for Delivery of Cargo from Storage; Historical Data Query Accessible to Database, managing data from purchase, storage and sale |

| Weighing Management |

Monitoring Weighing Process; Weighing Data-Collection; Anti-Cheating for Custody Transfer Metering |

| Access Management |

Vehicle Entrance Management; Vehicle Release Authority; Recording |

| Dispatch Management |

Arrangement for Loading Process |