Catalog

- Overview

- Brief Tech-Parameter

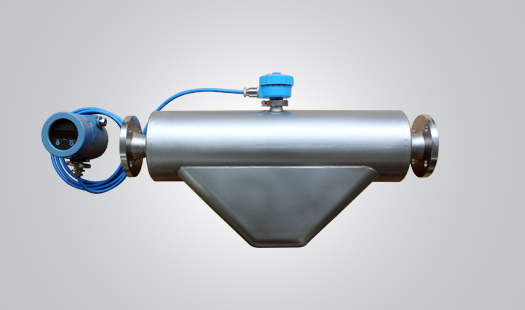

Coriolis Flow Meter | CG Series (Optimal & Economical)

Your Global Partner for Custody Transfer Metering

ATEX / IECEX Certified by TÜV SÜD Product Service GmbH

The CG Series coriolis flow meter is rigorous in design to achieve excellent and trusted metering performance on higher metering standards. This series coriolis mass flow meter has been stably serving onshore and offshore application covering modularized metering packages, LACT unit, crude oil metering, vessel bunkering, LNG metering, etc.

The CG Series coriolis flow meter is always catering to users' needs by delivering the best-in-class performance to higher standard liquid & gas metering.

The product design, manufacturing, calibration and storage comply with the Nation standard of GB/T31130-2014.

Measurement Principles

As a practical application of the Coriolis effect, the coriolis mass flowmeter operating principle involves inducing a vibration of the measuring tubes inside of the sensor through which the fluid passes. The vibration gives rise the coriolis effect, which will cause a phase difference between the inlet and outlet. The mass flow of the fluid will be measured by monitoring and analyzing the phase difference of the sensor signal from the inlet and outlet pick-off.

The vibration frequency of the measuring tubes changes when the fluids' density change. Based on the changing resonance frequency, the fluids' density could be calculated reliably.

The coriolis meter integrates with precise temperature sensor. In addition to temperature measurement and output, it is also internally used for compensation of flow and density.

Consequently, in addition to direct measurement on mass flow, density and temperature, the coriolis flow & density meters could also measure volumetric flow by calculation.

Main Catalog of CG Series Coriolis Flow Meter

- Standard Type: Custody Transfer / Fiscal Metering Class

- Cryogenic Type: Extremely Low Working Temperature -196~60 Deg. C

- High Pressure Type: 30MPa (Standard)

- High Temperature Type: -40 to 350 Deg. C

- Anti Corrosive Type: Wetted Part Material to be Hastelloy C22

- Sanitary Type: Qualified for Food & Beverage Application

Typical Applications

Crude Oil Custody Transfer / Fiscal Metering

- Onshore and Offshore Metering

- Crude Oil Loading & Unloading by Rail

- Crude Oil Loading & Unloading by Truck

- Crude Oil Loading & Unloading by Vessel

Marine Bunkering

- Marine Bunker Fuel Custody Transfer / Fiscal Metering

- Marine Diesel Oil Custody Transfer / Fiscal Metering

- Marine LNG Bunkering via Vessel or Floating Terminals

- Heavy Fuel Oil Custody Transfer / Fiscal Metering

Flow Metering for Aviation, Aerospace, Military

- Jet Fuel Custody Transfer / Fiscal Metering

- Engine Fuel Custody Transfer / Fiscal Metering

- Diesel Fuel Custody Transfer / Fiscal Metering

- LNG Custody Transfer / Fiscal Metering

- Liquid Oxygen Loading

- Liquid Nitrogen Loading

LPG, Propane Metering

- Modularized Metering Skids Metering for Onshore and Offshore

- Deployment for Lease Automatic Custody Transfer unit (LACT)

- LPG, Propane Custody Transfer / Fiscal Metering by Truck, Rail

General Technical Index

| Model | Size | Max. Flow | Max. Working Press. | Accuracy Class | Zero Stability (kg/h) |

| CG-06 | 6 mm | 20 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 0.04 |

| CG-15 | 15 mm | 50 kg/min | 25 MPa | 0.10, 0.15, 0.20 | 0.12 |

| CNG-15 | 15 mm | 70 kg/min | 25 MPa | 0.10, 0.15, 0.20 | 0.19 |

| CNG-20 | 20 mm | 120 kg/min | 25 MPa | 0.10, 0.15, 0.20 | 0.36 |

| CG-25 | 25 mm | 200 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 0.62 |

| CG-40 | 40 mm | 500 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 1.60 |

| CG-50 | 50 mm | 1000 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 2.38 |

| CG-80 | 80 mm | 3000 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 7.05 |

| CG-100 | 100 mm | 5000 kg/min | 4 MPa | 0.10, 0.15, 0.20 | 12.0 |

| CG-150 | 150 mm | 600,000 kg/h | 4 MPa | 0.10, 0.15, 0.20 | 15.0 |

| CG-200 | 200 mm | 1,200,000 kg/h | 4 MPa | 0.10, 0.15, 0.20 | 25.0 |