Overview

CMS Series Oil-Gas Separated Measurement System is multi-phase flow Measurement system researched & developed in our company. CMS employs advanced Gas-Liquid Cylindrical Cyclone Separated Technology to separate Gas & Liquid, and uses Coriolis Mass Flow Meter to measure the accuracy of gas & liquid. Because of the high accuracy, wide measure ratio, without maintain and strong flow characteristics of Coriolis Mass Flow Meter, meanwhile is also not affected by liquid physical characteristics(such as density & viscosity), and the CMS is very specially applied to oil field complicated flow condition, varied flow, varied water content, etc. complicated mining industry.

CMS Series Oil-Gas Separated Measurement System can measure and display mixed liquid total mass, instant flow and density, meanwhile which can also calculate water content ratio, oil production at the suitable industry condition, and the accuracy error totally meets international

Every elements of CMS Series Oil-Gas Separated Measurement System meet the below relevant regulations and standards during the process of design & production:

GB50350-2005

Oil-field Oil-Gas integrated transport design regulation

GB 3836

Explosion Ambient usage Ex-proof electric equipment

SY/T6682-2007

Using coriolis mass flow meter to measure liquid hydrocarbons flow

SY 0402-2000

Petroleum gas station technological pipeline project construction & acceptance regulation

SY/T0090-2006

Oil-gas field & pipeline instruments controlled system design regulation

SY/T0515-2007

Separator regulation

Typical Application

• Single Well Measurement

• Well Group Measurement

• Measure Station Measurement

• Separated Team Measurement

• United Station Measurement

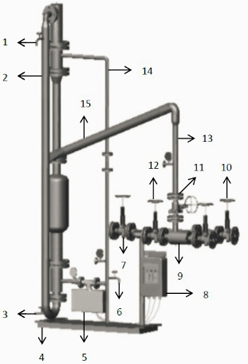

Structure Schematic Diagram

Structure Schematic Diagram

| Sr. | Description |

| 1 | Gas Phase Exhaust Valve |

| 2 | Separated Pipe |

| 3 | Liquid Phase Exhaust Valve |

| 4 | Base |

| 5 | Mass Flow Sensor |

| 6 | Sampling Valve |

| 7 | Mixed Control Valve |

| 8 | Mass Flow Transmitter |

| 9 | Filter |

| 10 | One-way Control Valve |

| 11 | Feed Control Valve |

| 12 | By-pass Valve |

| 13 | Feed Pipe |

| 14 | Gas Phase Circulating Flow Pipe |

| 15 | Jet Pipe |

Working Principle

Gas-Liquid two-phase separated working principle

CMS working principle as per the above schematic diagram, entrance is connected by down dip angle pipeline and vertical pipeline, multi-phase flow goes into main separator through feed liquid pipe. Because of rotational flow function, Centrifugal Force, Gravity and Buoyancy Force become a turnover pyramid type vortex surface in separator. Large density liquid phase flow into separator bottom along the wall of vertical pipeline, while small density gas phase goes up to the top of separator along the center of vortex, finally gas phase and liquid phase separately discharged from separator top and bottom. Meanwhile adjusts liquid level and pressure through automatic control system to achieve two phases completely separated, and the separated liquid phase and gas phase separately measured by liquid and gas single phase flow meter. The precision design of separator is the key to ensure whole performance of system. Accuracy separator design will make sure well separate of liquid and gas phase under the complicated industry condition, to ensure measure accuracy of instrument. According to customers' supplied industry condition, measured accuracy requirements, our company can re-amend CMS Series size, and to design, manufacture and relevant instrument control system. CMS covers a wide application, including current major oil-well and process integrated transfer.

CMS Control Principle

CMS employs automatic control principle, according to industry condition flow type simulation on-site, meanwhile considering completely of the relationship among liquid level, pressure, gas-liquid flow and valve location, to composite perfect complex adjustment system. Through building correct gas-liquid separated model and using perfect control system, to achieve good gas-liquid balance of separator and get the reasonable separated effects, then to ensure the accuracy of measurement.

Measurement Principle

After separated, flow liquid separated into gas-phase and liquid-phase, and gas-phase can be measured by gas flow meter, liquid-phase can be measured by mass flow meter. Meanwhile because of mass flow meter special principle, which can calculate the flowed pure water and pure oil mass by outputting on-site pure water and pure oil density, to achieve the single-measurement function of oil-well produced oil.

Moreover this device can also analyze & deal with the measured parameter by computer, then automatically to generate liquid, gas, water(oil) instant parameter curved line, daily production report etc., also can achieve the remote monitor of measured parameter as per customers' requirements.